This Summer, our MVHR team got a new home. Over the last five months, we have completed a radical retrofit of the Mill Building Unit, aka unit 4, at our headquarters at Heath House, Golcar.

Over a series of themed blogs, we have told the story of the retrofit:

Mill office radical retrofit: A ‘box within a box’

Mill building office radical retrofit: Floors & windows

Mill building office radical retrofit: Heating & Insulation

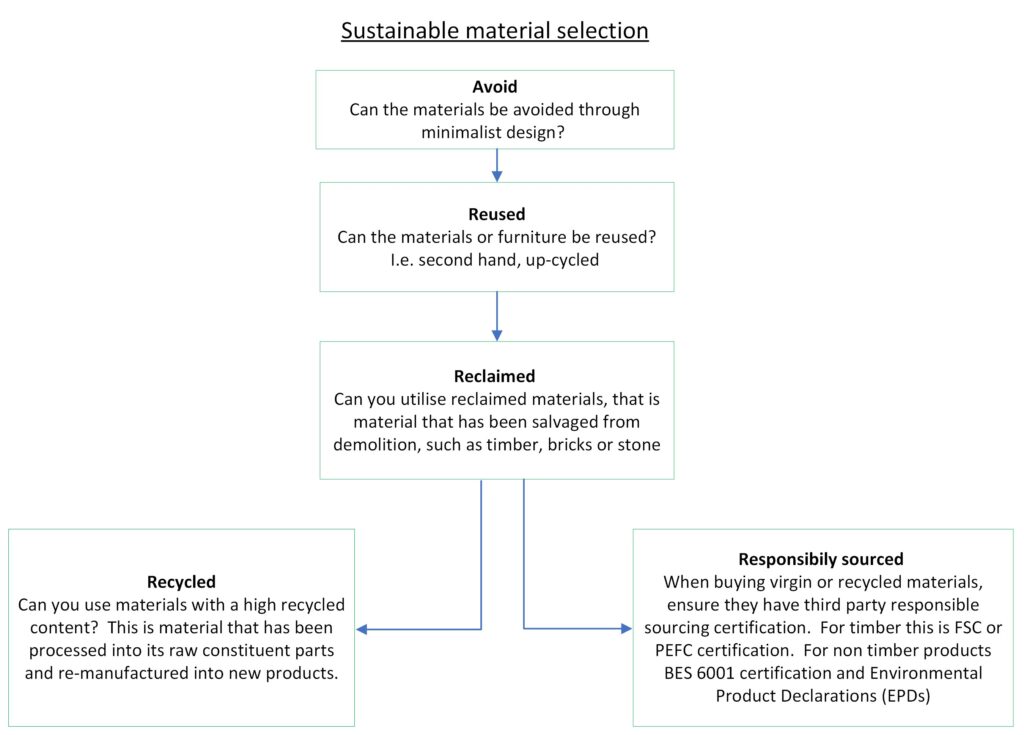

In this fourth and final chapter, we will take a look at the materials we chose for the fittings, fixtures and furniture for the building. Here we cover how we approached the choice of these materials based on sustainability considerations.

Our principles of consideration for products

When it comes to finishing a retrofit project on a building, it’s important to have holistic sustainability in mind right until the end of the project. It is very easy for environmental, and health considerations to be lost in the excitement of completing a project especially when it comes to what materials you might choose for the final features of the building like the paint, floor finishes and furniture. In order to ensure that the best sustainability principles were considered right to the end of the project, we had a few key rules that we attempted to follow. These were:

- Responsibly sourced timber – Where was the timber sourced from? Is the timber used FSC?

- Indoor air pollutants – Are the materials going to contribute to good indoor air quality?

- Recycling – Could we reuse or recycle materials project rather than source new products?

Timber products

Our history is all about FSC timber, we were the first company in the UK to sell FSC certified timber windows. We believe responsibly sourced wood for any self-build, retrofit, or indeed any building project, is paramount. So when it came to the Mill Building Office, we wanted to ensure that our choice of timber inside the building adhered to the same standards we had used for the timber in the frame of the building.

With the exception of plywood, the use of which we tried to minimise, no hardwood was used inside the building. The kitchen was sourced from Howdens who use FSC carcasses containing minimum 70% FSC sourced timber. All skirting, architraves and door linings in the building were pine softwood and we didn’t use any MDF. This avoided the VOCs (volatile organic compounds) found in MDF being released into the office’s environment.

Paints

We agreed with our decorating contractor that we wanted very-low VOC content paints. Many paints, including those from the best known paint brands, are now water based with the amount of VOCs in the product usually clearly labelled on the back of the tin. With this in mind, it isn’t difficult to select paints that contain less harmful ingredients. The low VOC content of the paints we chose was apparent during the painting process when it was almost impossible to smell them as they were being applied. The strong smell of paint that you might associate with traditional oil-based paints was just not present. Even after the paint has dried, our choice of low VOC, water-based paints ensures that the occupants of the office aren’t breathing in fumes and compounds that could be detrimental to their health.

Recycled Materials

In the walls and ceilings, we selected mineral wool from Knauf insulation. This uses a bio-based binder which is formaldehyde and phenol free, and therefore has a lower VOC risk. It is also made from a minimum of 80% recycled glass content. Knauf mineral wool insulation is a medium performance insulation (conductivity range of 0.044 W/mK to 0.032 W/mK) but has a much lower environmental impact due to its high recycled content. It is available at most building merchants.

As well as the walls and ceilings, we looked to recycled materials for our floors too. The carpets tiles called ‘Recover’ which we selected are made from an 80% recycled polyester and they are manufactured locally in Wakefield.

All the office furniture was almost entirely obtained from local pharmaceutical company Thornton and Ross, who were moving offices and no longer needed their existing desks and chairs. As such, we saved a large amount of furniture from going to incineration!

Bathrooms

For the bathrooms, we used some of our own old stock dual flush, low water use toilets, which once again made use of materials that may instead have found their way into a recycling plant or worse still incineration.

We have also fitted a shower in the office, which allows staff who cycle to work to freshen up before their day begins, which of course is beneficial to them and their colleagues. (The cycle up the hill to Golcar courses any cyclist to break a sweat!)

Lighting and electrics

The lighting is all low voltage LED strip batons which have been surface fitted to the ceilings. They ensure that light levels at desks for office users is more than ample when measure by light meter.

A glass foyer was added at the entrance to the office to ensure that as much natural light as possible enters the building. Access to natural light has been shown to positively affect the productivity of people in an office environment.

Appliances

Now while we (Bill and Adam) dispute the benefits of washing up vs a dishwasher. (Bill believes in the meditative power of washing up and having some time to think). We chose a dishwasher for the office, as dishwashers, will use less water with one full wash load than multiple episodes of running hot water and washing up by hand.

Plants

The benefits of nature to an office or home environment space are well known. As well as the aesthetic benefits they bring to an office, plants also actively ‘clean the air’ by removing pollutants from the air as they respire and photosynthesize.. We added several plants to the office and staff have continued to add them to their desks and workspaces.

The benefits of nature to an office or home environment space are well known. As well as the aesthetic benefits they bring to an office, plants also actively ‘clean the air’ by removing pollutants from the air as they respire and photosynthesize.. We added several plants to the office and staff have continued to add them to their desks and workspaces.

The combination of the cascade MVHR system, the low VOC content of materials used, and the plants means that the air quality of the new office is exceptional. The MVHR system installed even has carbon dioxide sensors fitted, which at times of high occupancy when carbon dioxide levels increase, ensures that the system draws in more fresh air, and extracts at a higher rate, thus increasing the ventilation of the space.

Throughout the entire project, we have worked hard to ensure than wherever possible both the sustainability and health aspects of the materials selected have been considered and have ultimately been chosen to bring the most benefits to all users of the office. We firmly believe we have created a unique, low energy and healthy office space for all staff at Green Building Store to work in.

Bill Butcher, Director & Adam Harper Construction Manager, Green Building Store

20th September 2022

Related Posts

- 51 Best Online Furniture Stores to Bookmark Now | Architectural Digest

- Pinterest and Article I.D. 6 outdoor design trends based on pinners' searches

- 38 Best Online Furniture Stores

- This Renovation in Toronto Is Inspired By a Love for California

- Interior Designers on the Most Iconic Furniture of All Time